DuraGates CGS-350.8G, Grande Carriage, Monobloc Body

Hardware

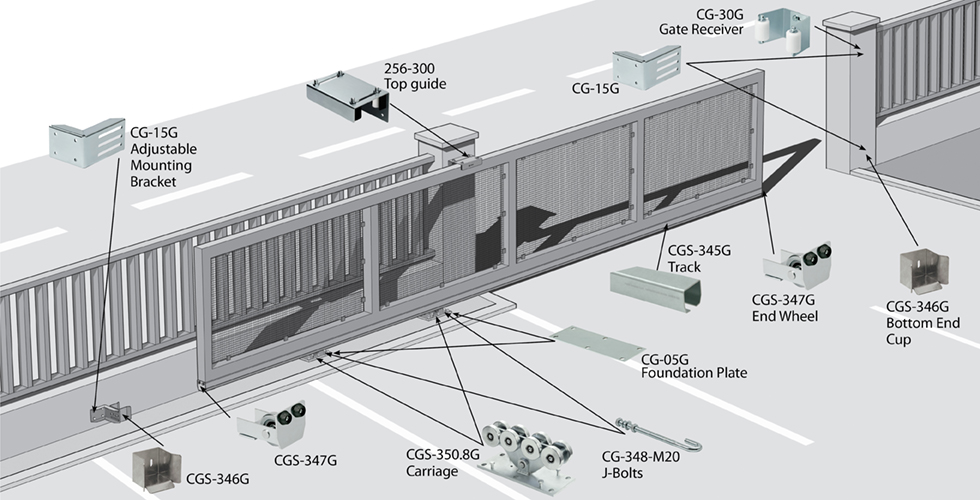

CGS-350.8G

DuraGates CGS-350.8G, Grande Carriage, Monobloc Body

Heavy duty 8 wheel carriages with sealed bearings. Large pivot allows for increased weight capacity, smooth sliding and stability. Larger wheel dimensions increase the weight capability and reduce wear and tear between wheels and tracks.

CGS-345G

Grande galvanized track

Build the gate right on the track. Galvanized steel track’s structural properties allow high loads without distortion. The track is made from low carbon steel alloy for excellent weldability. Available in 20’ and 10’ lengths.

CGS-347G

End Wheel for UL325 Compliance

The End Wheel bolts into each end of the track and complies with UL325 safety code for automated gates. It gives a finished look and prevents dirt, snow, etc. from getting inside the track and interfering with the operation of the carriages. The wheel allows the gate to roll into the bottom

end cup without scraping the paint or galvanized coating.

CG-21G

End Stopper without wheel for UL325 Compliance

he End Stopper bolts into each end of the track and complies with UL325 safety code for automated gates. It gives a finished look and prevents dirt, snow, etc. from getting inside the track and interfering with the operation of the carriages.

CGS-346G

Bottom End Cup

This cup receives the track in either the closed or open position. The beveled leading edge allows for a smooth entry and stop. The cup holds the gate steady, reducing vibrations from wind conditions, etc., and prolongs the life of the carriages and gate operators.

CG-25G

Lower gate receiver with nylon roller

The lower gate receiver will support the gate in the open or closed position while it rests on a nylon roller.

CG-348-M20

J-Bolt, Galvanized

Galvanized J-Bolts are set into the concrete pad as it is poured. Once it has cured, the carriages

are then secured to the pad using these bolts. J-Bolts are the preferred method of anchoring the carriages to the concrete pad. Wedge anchors with two-part epoxy will work but need to be sized to each load according to manufacturer’s recommendations.

CG-05G

Foundation Plate

The foundation plate provides a solid base for leveling the carriage on the pad. It prevents the leveling screws from digging into the pad and causing long term alignment issues. By keeping the carriage bottom from being in direct contact with the concrete pad, it slows down corrosion effects.

For Top Guides and Accessories

Gate gallery

Commercial Gate in Tupelo, Mississippi

Reference Number : D195

Maloney Glass & Overhead Door needed a new gate to their corporate office. They wanted to use a system that…

Large, Heavy Steel Gate at a Substation in New Mexico

Reference Number : D192

This automated gate has a 20 foot opening and is 14 feet tall and uses Duragates Grande Carriages. This carriage…

Steel Framed and Wooden Gate

Reference Number : D166

This New Jersey resident wanted a gate to secure his property. A swing gate was not feasible as…

Chain Link Gate at Commercial Facility in New Jersey

Reference Number : D165

Model CGS-350.8G was the perfect solution for this 40ft gate at this commercial facility in New Jersey. The…

Gate at George Washington University

Reference Number : D153

The Grande DuraGates Model, CGS-350.8G was used for this cantilever sliding gate. George Washington University needed a sturdy…

Lift Station in Rio Rancho, NM

Reference Number : D125

The City of Rio Rancho, New Mexico approached Scott's Fencing hoping their company would have a solution for…

Government Facility in New Mexico

Reference Number : D108

This large gate needed our largest model CGS-350.8G. A very simple gate design, the application called for high…

Texas A&M University

Reference Number : D109

This high profile project has a unique lattice work design. Any regular sliding gate hardware would have compromised…

Private residence in Virginia

Reference Number : D110

This highly ornamental steel gate spans an opening of over 25ft. With the DuraGates hardware you don’t need…

Private Residence in Virginia

Reference Number : D111

Unique requirement: This highly ornamental steel gate spans an opening of over 30ft. The short fence along the…

Spring Street Salt Shed

Reference Number : D112

Island Steel & Detailing Corporation did a fantastic job fabricating and installing two large gates using our DuraGates…

Residential Gate in New Jersey

Reference Number : D117

This residence in North Jersey is on a busy street and did not have the space for a…